When most homeowners think about replacing their roof, shingles are usually the focus. However, a truly durable, code-compliant, and long-lasting roofing system includes at least 7-10 other components, each playing a critical role in weatherproofing and structural protection.

At Litespeed Construction, a Asheville-based roofing contractor known for transparency and craftsmanship, we frequently educate customers on what really goes into a “new roof besides shingles.”

Whether you’re planning a new roof in Asheville, NC, or researching roofing systems anywhere in the U.S., this in-depth article breaks down every major material and layer required — including government-recommended standards, installation codes, and cost/benefit analysis to help you make informed decisions.

Key Takeaways

💡Your roof is a multi-layer system

💡Underlayment & Ice/Water Barriers are essential

💡Ventilation impacts longevity & energy efficiency

💡Flashing and Drip Edge prevent hidden damage

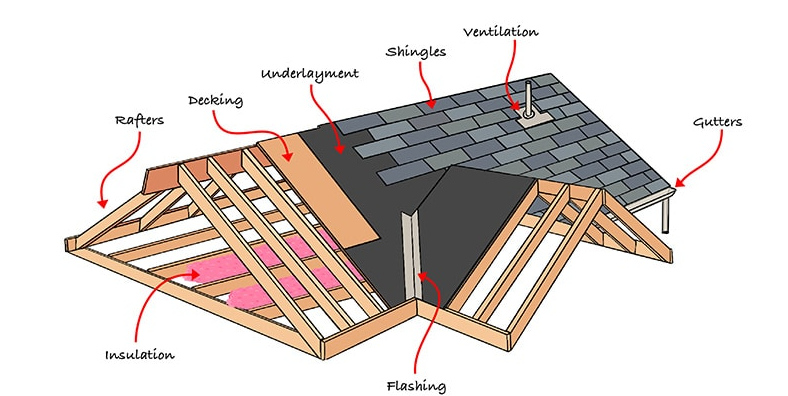

A Closer Look at Roofing Materials Besides Shingles

Let’s explore each roofing material found in a complete roof system, what it does, and why it matters.

1. Roof Decking (Sheathing): The Structural Base

Roof decking provides the foundation for all roofing materials. Typically made from OSB (Oriented Strand Board) or CDX plywood, decking supports all other layers and connects directly to your home’s framing.

Common Types of Decking

| Material | Description | Cost (per sq ft) | Load Rating |

|---|---|---|---|

| OSB | Engineered wood panels | $0.70 - $1.20 | 24/16 APA-rated |

| CDX Plywood | Cross-laminated wood veneer | $1.20 - $2.50 | Stronger than OSB |

| Plank Sheathing | Solid boards, often 1x6 or 1x8 | $1.50 - $3.00 | Found in historic homes |

📘 Source: APA – The Engineered Wood Association

Why It Matters:

- Must be in “sound condition” according to IRC Section R905.1.5

- Compromised decking = structural danger + water intrusion

2. Underlayment: Moisture Defense Layer

Beneath the shingles lies the roof underlayment, a moisture barrier that prevents wind-driven rain and snow from reaching the deck.

Types of Roof Underlayment

Types of Roof Underlayment

| Type | Composition | Waterproof Rating | Typical Lifespan |

|---|---|---|---|

| Asphalt Felt (15 lb or 30 lb) | Organic or fiberglass mat with asphalt coating | Water-resistant | 10–15 years |

| Synthetic Underlayment | Polypropylene, polyethylene fabrics | Water-repellent | 20–50 years |

| Self-Adhering Membrane | Rubberized asphalt | Fully waterproof | 20–30 years |

Code Requirement:

According to IRC R905.2.3, underlayment is required under all asphalt shingles and must be properly overlapped and fastened.

🛑 Cheap felt paper can degrade quickly — we at Litespeed Construction recommend synthetic underlayment for durability and slip-resistance during install.

3. Ice and Water Shield: Protection Where It’s Needed Most

This peel-and-stick waterproof barrier is applied in vulnerable roof zones:

- Eaves (to stop ice damming)

- Valleys

- Around chimneys, skylights, and vents

Required in colder climates by the IRC R905.1.2 but recommended in heavy-rain regions like Western North Carolina.

| Feature | Benefit |

|---|---|

| Self-sealing around nails | Prevents water entry |

| High-temp variants available | Compatible with metal roofs |

| Prevents leaks during ice dams | Essential for roof longevity |

📘 EPA Data: Ice dams can cause $5,000–$10,000 in interior water damage per event.

4. Drip Edge: Directing Water Off the Roof

Installed at the eaves and rake edges, drip edge flashing protects:

- Fascia boards

- Soffits

- Roof edge decking

It directs water into gutters rather than under the shingles.

Materials Used:

- Aluminum (standard, corrosion-resistant)

- Galvanized steel

- Copper (high-end aesthetics)

Code Note:

IRC R905.2.8.5 mandates drip edge on all eaves and rakes for asphalt shingle systems.

🔧 Installation Detail: Drip edge goes under the underlayment at eaves and over at rakes.

5. Flashing: Waterproofing Roof Junctions

Flashing protects any interruption in the roof plane, including:

- Chimneys

- Skylights

- Roof-wall transitions

- Vents and pipe penetrations

| Flashing Type | Where Used | Recommended Material |

|---|---|---|

| Step Flashing | Walls and dormers | Galvanized steel or aluminum |

| Counter Flashing | Chimney faces | Copper or steel |

| Vent Pipe Flashing | Plumbing vents | Rubber collar with aluminum base |

| Valley Flashing | Roof valleys | W-style aluminum or steel |

📘 According to NRCA (National Roofing Contractors Association), 90% of roof leaks are due to flashing issues.

6. Ridge Cap Shingles: The Roof’s Crown

Specially designed shingles used at the roof’s peak, protecting:

- Ridge vent openings

- Structural ridgeline

- Aesthetic finish

Designed to match and complement the main shingle type, ridge caps are thicker and more flexible.

Manufacturer Examples:

- GAF Ridge Cap Shingles (Seal-A-Ridge)

- Owens Corning (ProEdge or DecoRidge)

🔐 Ridge caps are key to wind resistance at the highest point of the roof.

7. Starter Strip Shingles

Starter strips are placed along the eaves and rakes to provide a straight, sealed edge for the first row of shingles.

Benefits:

- Protects against wind uplift

- Prevents shingle blow-off

- Ensures manufacturer wind warranty compliance

📘 GAF requires proper starter strip usage to validate limited lifetime warranties.

8. Roof Ventilation: Invisible, But Vital

Poor roof ventilation = trapped moisture + overheating = early shingle failure and mold.

Types of Roof Vents

| Vent Type | Location | Function |

|---|---|---|

| Ridge Vent | Peak | Exhaust hot air |

| Soffit Vent | Eaves | Intake fresh air |

| Gable Vent | Side walls | Passive exhaust |

| Powered Vent | Roof slope | Active exhaust |

U.S. DOE Recommendation: 1 sq ft of ventilation per 300 sq ft of attic space, split equally between intake and exhaust.

9. Roofing Fasteners: Holding It All Together

Using galvanized or stainless steel roofing nails, fastened per manufacturer and code guidelines, is essential.

| Nail Type | Use Case | Why It Matters |

|---|---|---|

| Roofing Nails | Shingles, underlayment | Ring-shank preferred for wind zones |

| Cap Nails | Synthetic underlayment | Plastic head helps hold materials securely |

| Flashing Screws | Flashing systems | Must be corrosion-resistant |

📘 In high-wind zones, improper nailing leads to shingle blow-offs — costing $3,000+ per incident.

Roofing System Overview Diagram

FAQs About Materials in a New Roof Besides Shingles

Up to 50 years depending on brand and UV exposure. Far superior to felt.

Only if it's structurally sound. Most roofs require partial or full replacement.

No — powered roof vents and solar fans provide active ventilation.

Only if installed properly with approved materials. Manufacturer warranties vary.

Approximately 35%–50% of the total cost of a professional roof replacement.

Not by code in all areas, but strongly recommended in valleys and around penetrations.

Galvanized ring-shank nails are most common; stainless steel in coastal areas.

Yes — request photo documentation from your contractor (Litespeed provides this).

Reduces heat and moisture buildup — extends roof life and improves HVAC efficiency.

Focusing only on shingles instead of the full roofing system.

Expert Insights: Why Litespeed Construction is Different

As GAF-certified roofing professionals, we ensure:

- All materials meet or exceed IRC/IBC codes

- Our installations comply with manufacturer warranty requirements

- Each customer receives a roofing system, not just new shingles

✅ Backed by 14+ years of experience

✅ Top-rated roofing contractor in Asheville, NC

✅ Committed to quality over shortcuts

Ready to Replace Your Roof in Asheville, NC?

Litespeed Construction doesn’t just “replace shingles.” We install full roofing systems that comply with code, climate, and manufacturer warranties.

💬 Schedule your FREE roof inspection today.

🔧 Serving Asheville & East Tennessee with craftsmanship and care.