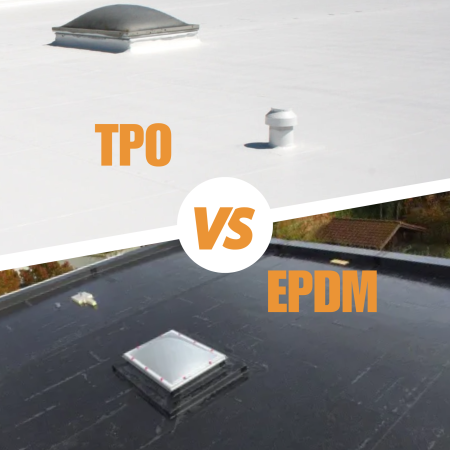

TPO vs. EPDM: Which Roofing Material is Better?

When it comes to commercial roofing, two of the most popular options are Thermoplastic Olefin (TPO) and Ethylene Propylene Diene Monomer (EPDM).

These materials dominate the market due to their durability, energy efficiency, and cost-effectiveness.

If you’re a business or property owner in Asheville, NC, understanding which material suits your roofing needs is essential.

This guide dives deep into the TPO vs. EPDM debate, backed by statistics and expert insights.

What Are TPO and EPDM Roofing Systems?

TPO Roofing

TPO is a single-ply roofing membrane made from a blend of polypropylene and ethylene-propylene rubber. Known for its reflective properties, TPO is often marketed as a more energy-efficient option. It is widely used in commercial buildings due to its durability and resistance to UV rays, chemicals, and heat.

EPDM Roofing

EPDM is also a single-ply membrane, but it’s made primarily from synthetic rubber. Known for its elasticity, EPDM has been a go-to roofing solution for over 50 years. It performs exceptionally well in cold climates and resists moisture, making it a strong contender for various roofing projects.

Key Differences Between TPO and EPDM

| Feature | TPO | EPDM |

|---|---|---|

| Material | Polypropylene and ethylene-propylene rubber | Synthetic rubber |

| Cost | $5.50–$9.50 per sq. ft. installed | $4.50–$8.00 per sq. ft. installed |

| Lifespan | 15–20 years | 20–30 years |

| Energy Efficiency | Highly reflective, great for hot climates | Absorbs heat, ideal for cold climates |

| Durability | UV and chemical-resistant | Excellent against water and cold weather |

| Maintenance | Moderate; prone to punctures | Minimal; highly resistant to wear |

| Installation | Heat-welded seams | Adhesive or mechanical fasteners |

Benefits of TPO Roofing

1. Energy Efficiency

TPO membranes reflect up to 87% of solar heat, reducing cooling costs significantly. The U.S. Department of Energy cites TPO as one of the most reflective roofing options, making it ideal for sunny climates like Asheville in the summer months.

2. Eco-Friendly

TPO is 100% recyclable at the end of its lifespan, aligning with sustainability goals. This feature is increasingly important for businesses prioritizing environmental responsibility.

3. Cost-Effectiveness

Though slightly more expensive than EPDM, TPO’s energy savings can offset the initial investment.

4. Durability

TPO resists UV radiation, mold, and chemical exposure, which prolongs its lifespan compared to less durable roofing options.

Advantages of EPDM Roofing

- Proven Longevity

With over 50 years of successful implementation, EPDM is a time-tested solution, especially in areas with cold and wet climates.

- Lower Initial Cost

EPDM is generally more affordable than TPO, making it attractive for budget-conscious property owners.

- Excellent Weather Resistance

EPDM is highly resistant to extreme cold, hail, and water pooling, which are common issues in Asheville’s diverse climate.

- Ease of Repairs

EPDM repairs are straightforward and inexpensive. Minor damage can often be fixed using simple patches and adhesives.

Common Repairs for TPO and EPDM Roofs

To help Asheville-based property owners understand commercial roof repair costs, here’s a detailed chart:

| Repair Type | TPO Average Cost | EPDM Average Cost |

|---|---|---|

| Seam Repairs | $500–$1,000 | $300–$600 |

| Puncture or Tear Repair | $200–$500 | $150–$400 |

| Recoating for Longevity | $1.50–$3.00 per sq. ft. | $1.00–$2.50 per sq. ft. |

| Leak Detection and Fixing | $300–$800 | $200–$700 |

| Flashing Repairs | $400–$1,000 | $300–$900 |

TPO vs. EPDM: Maintenance and Durability

– TPO Maintenance: While durable, TPO membranes are more prone to punctures, especially during installation. Regular inspections are crucial to prevent costly damage.

– EPDM Maintenance: EPDM membranes require minimal upkeep. Their black rubber surface is resistant to dirt and debris, reducing the need for frequent cleaning.

Environmental Considerations

The TPO vs. EPDM debate also includes environmental factors. TPO is highly reflective, reducing the heat island effect in urban areas. EPDM, on the other hand, is an excellent insulator, minimizing heating costs in colder months. Both materials are recyclable, but TPO’s eco-friendly manufacturing process gives it a slight edge.

Pros and Cons of TPO vs. EPDM

TPO Roofing

Pros

– High energy efficiency

– UV and chemical resistance

– Eco-friendly and recyclable

Cons

– Higher installation cost

– Requires professional installation for optimal results

EPDM Roofing

Pros

– Affordable upfront cost

– Proven longevity in cold climates

– Simple repairs and maintenance

Cons

– Less energy-efficient in hot climates

– Black surface absorbs heat

How to Choose the Best Option for Your Asheville Property

When choosing between TPO and EPDM, consider the following factors:

– Climate: TPO is better for warmer climates, while EPDM excels in colder regions.

– Budget: EPDM offers a lower upfront cost, but TPO may save on energy bills long-term.

– Roof Design: TPO is better for flat roofs, while EPDM can adapt to varied roof shapes.

Web Ratings for TPO and EPDM Roofing

| Category | TPO Rating (1–5) | EPDM Rating (1–5) |

|---|---|---|

| Energy Efficiency | 5 | 3 |

| Durability | 4 | 4.5 |

| Ease of Installation | 3.5 | 4 |

| Maintenance Cost | 3.5 | 4.5 |

| Affordability | 4 | 5 |

FAQs About TPO and EPDM Roofing

EPDM typically lasts 20–30 years, while TPO averages 15–20 years.

TPO is more energy-efficient due to its reflective surface.

Yes, both can be installed on residential roofs, though they are more common for commercial buildings.

TPO may require annual inspections; EPDM maintenance is less frequent.

EPDM may perform better in Asheville’s cold winters, while TPO excels during hot summers.

Yes, both are recyclable, but TPO has a greener manufacturing process.

Yes, both materials can be repaired easily by professionals.

EPDM is easier to install, especially on irregular surfaces.

Yes, manufacturers offer warranties for both TPO and EPDM roofing systems.

TPO is heat-welded, while EPDM uses adhesives or mechanical fasteners.

TPO vs. EPDM in Asheville, NC

For Asheville, NC property owners, the TPO vs. EPDM debate boils down to your specific needs. TPO is ideal for energy savings in sunny climates, while EPDM offers unmatched durability in colder conditions. Consult a trusted local roofing contractor to assess your building’s unique requirements.